Spaceflight Hardware

Overview

Intrinsyx engineers and delivers flight-certified hardware for NASA and commercial missions, supporting end-to-end processes from vendor fabrication to integration, testing, and flight readiness. We operate under strict NASA configuration management standards, ensuring traceability, quality assurance, and compliance with ISS and mission-specific requirements. Our team manages procurement, inspection, limited assembly, and pre-ship reviews across hardware built for microgravity and deep space environments.

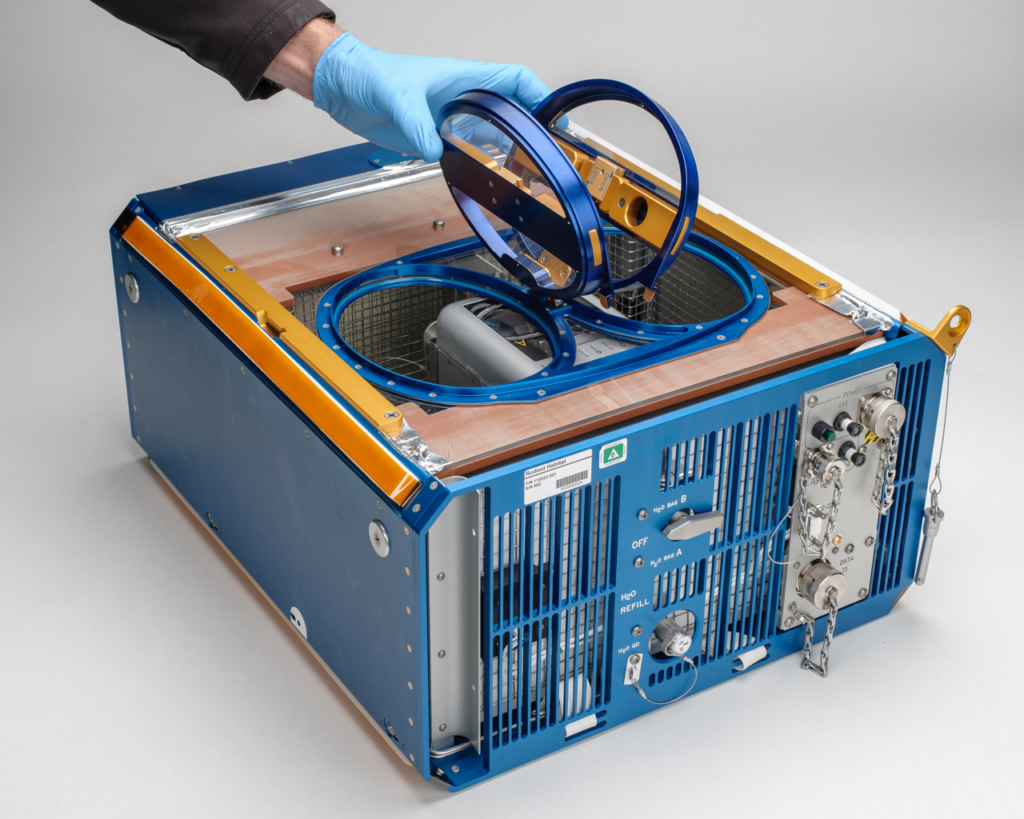

Rodent Research

Since 2017, Intrinsyx has supported NASA’s Rodent Research program by designing, building, and sustaining critical spaceflight hardware used in the transport and habitat of live animals aboard the International Space Station. These flight systems ensure safe launch, on-orbit operations, and return of rodent payloads for life sciences research in microgravity.

Cost-Effective Flight Hardware Build

Fabrication of core flight hardware: Habitat, Transporter, Access Unit

Efficient Hardware Sustaining

Full lifecycle support: Spares, Refurbishment, Cleaning, Flight-Ready Delivery, Verification & Validation

Hardware Upgrade

Intrinsyx developed a full end-to-end camera control system, enhancing NASA’s machine vision capabilities for the Rodent Research program: Integrated NVIDIA single-board computer, custom control board and power board, and all supporting integration, testing, and V&V.

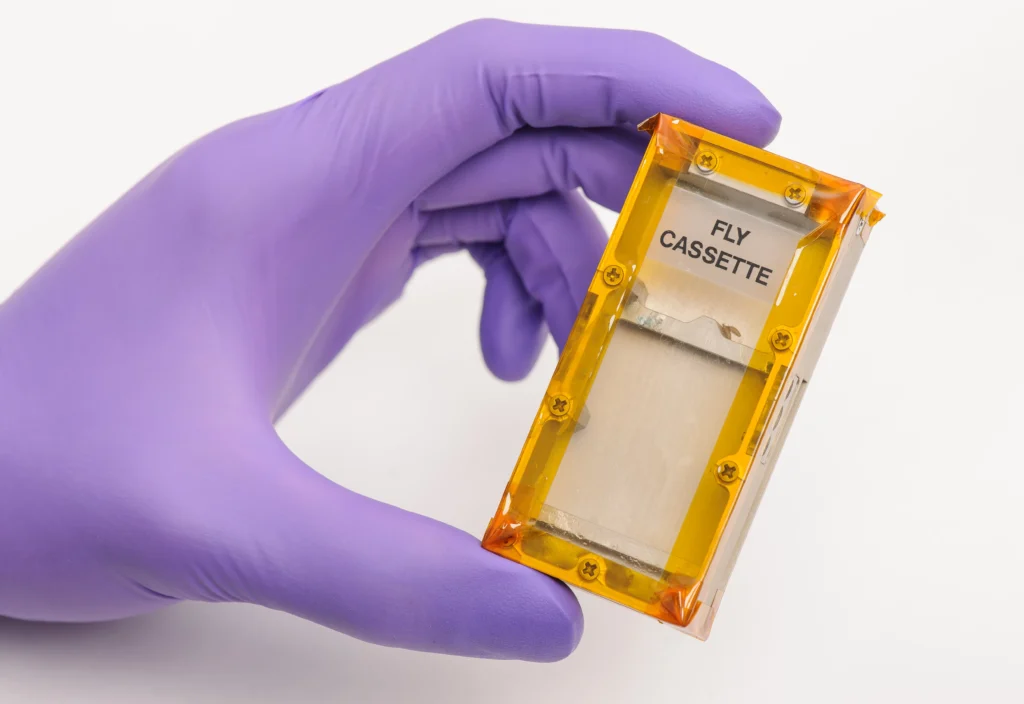

Fruit Fly Lab

Fruit Fly Lab (FFL) is a compact life sciences experiment designed to study genetic and physiological responses to spaceflight using Drosophila melanogaster (fruit flies). The platform integrates 1080p HD video capture, environmental sensors (temperature, humidity, CO₂, O₂), scheduler firmware, and the STELLA command/data interface.

Hardware Integration & Innovation

FFL-1: Centrifuge-based system simulating both 1G and microgravity environments, Express Rack compatible

FFL-2, FFL-3, HEART FLIES: Vial-based soft stowage platform housing 5,500 flies across 90+ genetic mutations

Flight-Proven & Sustainment

Intrinsyx supported refurbishment and flight readiness for four spaceflight missions, including full environmental monitoring and payload verification.

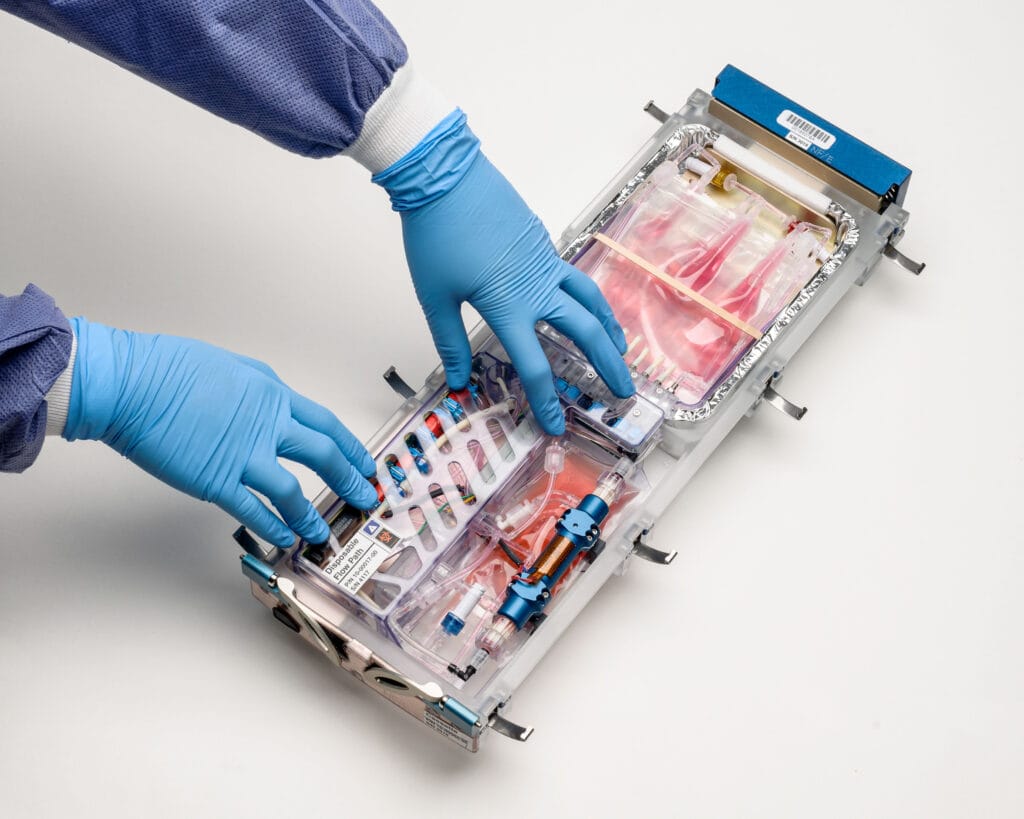

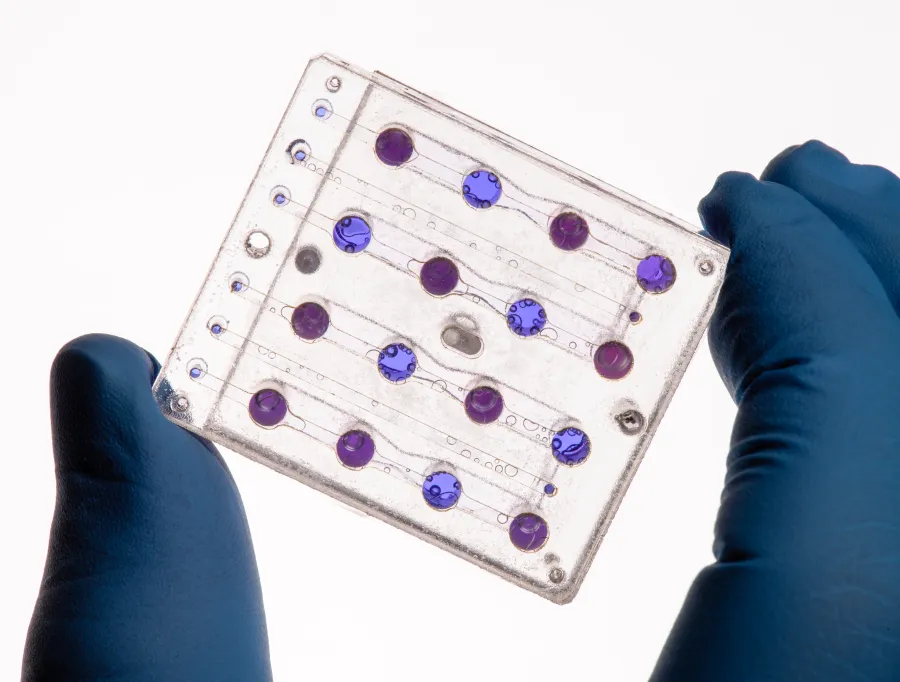

BioCulture System

The BioCulture System is a flight-certified, ten-cassette fluidic platform designed to support advanced cell science research aboard the International Space Station. Intrinsyx contributed to the engineering and system integration of this modular platform across two successful flight missions.

Hardware Engineering & System Development

Supported end-to-end system integration, including fluidic systems, firmware, and cassette-level engineering

Developed and tested ground and flight hardware to meet ISS payload interface and operational requirements

Assisted in science verification testing, demo flight prep, and mission level V&V procedures for launch readiness

Platform Replication & Support Systems

Contributed to development of the PI Start Kit, a ground-based BIOS replica supporting experiment development and hardware verification

Provided support for a three-cassette prototype system integrating hardware, firmware, and graphical user interface (GUI)

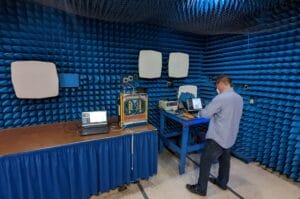

BioSentinel

Launched aboard NASA’s Artemis I mission in November 2022, BioSentinel is a 6U CubeSat and the only biological experiment spacecraft traveling into deep space. It continues its journey – gaining 16 million miles from Earth each year – while studying the effects of deep space radiation on living organisms.

ISS Payload Retrofitting

Engineers at Intrinsyx retrofitted the biosensor payload for compatibility with the ISS Express Rack, enabling ground-based and orbital testing environments.

Need help with your project? Get in touch!

Click here to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.